Exploring opportunities for a sustainable maritime career

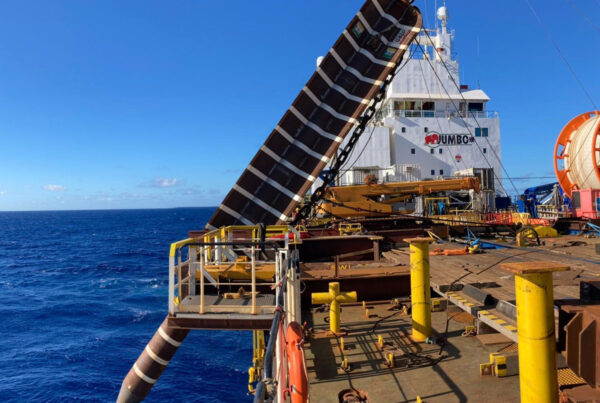

NEWS Engaging with students to explore careers and maritime innovation and sustainability Jumbo welcomes Hanze Hogeschool Groningen students On 16th February, Jumbo welcomed a group of nine mechanical engineering students…